How to Reduce Generator Fuel Consumption: 7 Powerful & Proven Ways for Maximum Savings ✅

Once your generator is properly installed, maintained, connected, and operating smoothly, you may encounter typical challenges. One significant issue is that your generator may not be fuel-efficient, consuming fuel at such a rapid rate that it becomes difficult to keep it adequately supplied when necessary.

To mitigate fuel consumption, it is essential to maintain the generator, ensure it has access to fresh air for combustion, and verify that the coolant is maintained at the appropriate temperature. Additionally, it is crucial to operate the generator only when necessary and to avoid both underloading and overloading the machine.

While these principles may seem straightforward, understanding the correct temperature thresholds during periods of high demand and knowing when to operate the generator requires some expertise. It is advisable to familiarize yourself with the fundamentals of optimizing efficiency.

Reasons for Reducing Generator Fuel Consumption

Reducing generator fuel consumption is not just about saving money—it’s also about efficiency, sustainability, and overall performance. When a generator consumes less fuel, it lowers running costs, reduces emissions, and extends the lifespan of the engine. Many users also notice that efficient fuel use leads to smoother operation and fewer maintenance issues over time.

Another key aspect people often consider alongside fuel efficiency is comfort. For instance, while learning how to reduce generator noise, you’re not only making your generator more pleasant to use but also improving fuel economy in some cases, since quieter machines often run more efficiently. Ultimately, cutting down on fuel use means a more eco-friendly and cost-effective solution without compromising on power.

There are two primary benefits to decreasing fuel consumption.

1. Lower Operating Costs

The expense of running a generator can be significant, depending on your location. For instance, an 8kW/10kVA diesel generator at full capacity typically consumes around 2.4 liters per hour. However, actual daily consumption often surpasses this average considerably.

2. Decreased Carbon Dioxide Emissions

On average, burning one gallon of diesel fuel releases approximately 10,084 grams of carbon dioxide into the atmosphere. This figure becomes even more alarming when considering the total number of power plants operating globally. By using less fuel, we can reduce the emission of harmful gases, leading to cleaner air and an improved quality of life.

With this in mind, let us explore strategies for reducing generator fuel consumption.

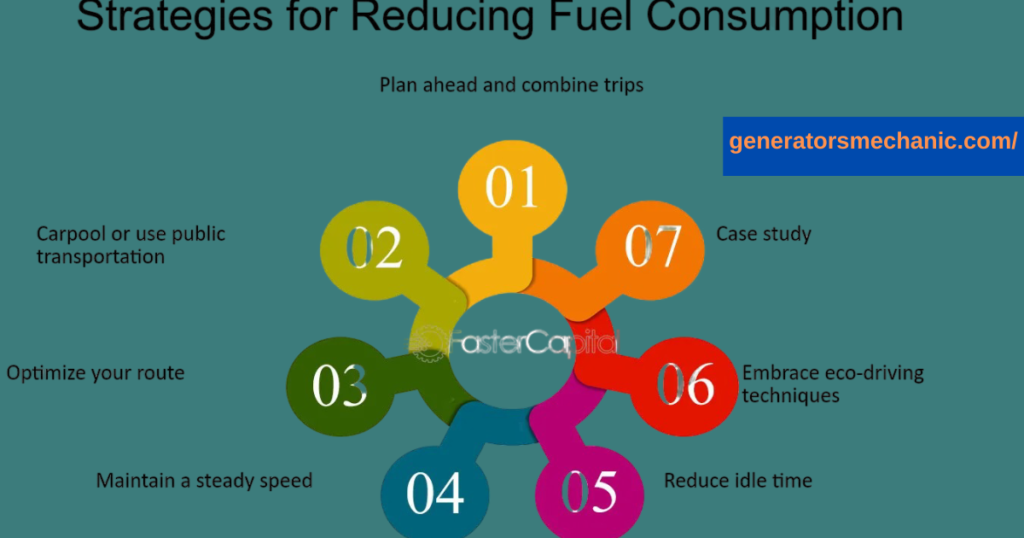

Strategies for Reducing Generator Fuel Consumption

Managing fuel efficiency is a top priority for anyone relying on generators for home, RV, or jobsite power. Simple strategies such as regular maintenance, using the correct load capacity, and choosing the right fuel type can significantly lower fuel consumption while keeping performance steady.

Another crucial step is keeping an eye on the carburetor, as a carburetor consuming too much fuel can quickly drain your supply and reduce efficiency. By cleaning or adjusting it when necessary and combining it with smart usage habits, you can ensure longer runtimes, lower costs, and a more reliable power experience.

While regular servicing of the generator is vital for maintaining fuel efficiency, additional measures can enhance its performance. There are several practices you can adopt to ensure that your generator operates more efficiently. The effective operation of a generator during use can lead to overall fuel savings; however, many owners mistakenly believe they can operate their machines without due diligence. It is essential to recognize that a generator will perform optimally when utilized for its designated purpose.

Here are eleven strategies to minimize fuel consumption in generators.

1. Operate only essential equipment

Limiting operations to only necessary equipment can significantly decrease the generator’s fuel consumption. This practice ensures that the generator is engaged solely when required.

Moreover, it is vital to maintain the generator properly and keep all filters clean. Implementing these adjustments will enhance the generator’s efficiency and reduce fuel usage.

2. Timely servicing of your generator

Regular maintenance of your generator is crucial for lowering fuel consumption. By ensuring your generator is serviced, you can maintain its efficiency and minimize fuel usage.

Several actions can be taken to service your generator effectively:

a) Ensure the correct fuel type is used. Utilizing an inappropriate fuel can lead to excessive fuel consumption.

b) Change the oil at regular intervals. As oil deteriorates over time, it can lead to increased fuel consumption by the generator.

c) Regularly inspect the air filter. A clean air filter can help optimize fuel consumption. It is advisable to seek professional servicing for your generator.

3. Avoid operating the generator below a 50% load

To achieve lower fuel consumption, refrain from running generators at loads less than 50%. Operating under such conditions forces the engine to exert more effort to generate the same power, thereby increasing fuel consumption.

4. Eliminate carbon deposits

Regular removal of carbon deposits is essential for reducing fuel consumption in generators. Over time, carbon accumulation can hinder the generator’s performance, causing it to work harder and consume more fuel. The generator should be inspected regularly for carbon buildup and any deposits should be removed promptly.

5. Timely maintenance with authentic replacement components

It is well-known that the operational costs associated with generators, particularly fuel expenses, can be substantial. Nevertheless, there are various strategies to help reduce these expenses.

Primarily, it is essential to ensure that the generator receives timely maintenance. This practice will help maintain its efficiency and minimize fuel consumption.

Additionally, utilizing authentic replacement components can contribute to lower fuel usage. Components specifically designed for generators will facilitate smoother operation and overall reduced fuel consumption.

6. Consider alternative energy sources

Adopting alternative energy sources can greatly decrease the fuel consumption of a generator. For instance, solar panels can produce electricity that may be utilized to power generators, thereby lessening the fuel needed for electricity generation.

7. Opt for a high-quality generator

When selecting a generator set, fuel efficiency is a vital consideration. There are various methods to lower fuel consumption, including choosing a high-quality unit and ensuring proper operation of the generator. A high-quality generator set typically exhibits a lower fuel consumption rate compared to inferior models, as they are designed to be more efficient and require less fuel to generate the same amount of power. Moreover, operating the generator correctly is crucial for reducing fuel consumption. This entails adhering to the manufacturer’s guidelines for operation and employing the most efficient practices possible.

8. Avoid Overloading Your Generator

One effective strategy to reduce fuel consumption is to avoid overloading the generator. This can be accomplished by ensuring that the generator’s output capacity aligns with the load it is required to support.

For instance, if a generator has a capacity of 5,000 watts and is tasked with powering two air conditioners rated at 1,500 watts each, the total load on the generator would be 3,000 watts. Consequently, the generator remains within its operational limits, preventing unnecessary strain and thereby decreasing fuel usage.

9. Ensure Adequate Ventilation

Proper ventilation is a critical factor in generator efficiency. It guarantees that fresh oxygen is available in the combustion chamber, which is essential for the effective and complete combustion of the air-fuel mixture.

Insufficient fresh oxygen supply can lead to increased fuel consumption and diminished efficiency of the engine. It is noteworthy that generators operating at sea level typically exhibit better efficiency compared to those situated at higher altitudes. The greater the amount of fresh oxygen available to the generator, the less fuel it will require.

10. Eliminate Carbon Deposits

During the combustion process, various components of the generator, including diesel and oil, heat up significantly, leading to the formation of grey carbon polymers that can adhere to valves, injectors, and piston tops. This buildup is often responsible for the black smoke commonly associated with diesel engines and can also negatively impact fuel efficiency.

Therefore, it is advisable to regularly remove carbon deposits and clean the generator as thoroughly as possible. There are multiple methods to achieve this, including the use of chemical solutions and manual cleaning of individual components. However, it is prudent to consult with the generator manufacturer before undertaking any cleaning procedures to ensure the correct approach is followed.

11. Maintain the Appropriate Cooling Temperature

To ensure optimal combustion of diesel fuel, the cooling water temperature must adhere to the specified standard. Deviations in water temperature or failure to meet certain conditions can lead to incomplete combustion, resulting in excessive fuel consumption, which can be easily mitigated.

What factors influence the fuel consumption of generators?

Several elements come into play when looking at what impacts the fuel usage of a generator. The load you put on the generator is one of the biggest factors — running it closer to maximum capacity will naturally burn more fuel. Engine efficiency, fuel type, and even weather conditions like temperature or altitude also affect how much fuel is consumed. Another crucial aspect is proper maintenance.

For example, making sure the generator carburetor adjustment screws are set correctly ensures the engine runs smoothly and burns fuel more efficiently. By balancing load, maintaining the engine, and using the right fuel, you can greatly improve fuel economy.

Several elements contribute to the fuel consumption of a generator.

- The brand of the generator can play a significant role, as some brands are designed to be more fuel-efficient than others.

- The age of the generator also impacts fuel consumption; typically, newer generators exhibit greater fuel efficiency compared to their older counterparts.

- Smaller generators generally consume less fuel than larger ones due to their reduced size.

- The load or electrical output required from the generator directly affects fuel consumption.

- The number of devices powered by the generator influences fuel usage, as a greater number of devices necessitates more electricity and, consequently, more fuel.

- Lastly, the maintenance of the generator is crucial; a generator that is not well-maintained will consume more fuel than one that is properly serviced.

Conclusion

Investing in a generator represents a significant financial commitment. By applying the aforementioned strategies to minimize fuel consumption, you can ensure that you are making an informed decision for your organization. Additionally, you will contribute to environmental protection by decreasing emissions and conserving fuel. Should you require further clarification on “how to reduce generator fuel consumption,” please feel free to reach out to us for assistance.

FAQs

1) Do generators consume less fuel with a lower load?

It is important to note that when a generator operates under a larger load, fuel consumption increases. Conversely, when the load is below 50%, fuel consumption is significantly reduced. The generator serves as a dependable backup power source during interruptions in the regular supply.

2) Does the generator consume more fuel when connected to devices?

If the generator is not operated beyond its capacity, an increased load will result in higher power and fuel consumption.

3) Is it possible to operate a generator without a load?

Generators operate under the principles of internal combustion engines, necessitating a specific load to function effectively. Operating a generator with insufficient or no load can lead to various issues, ranging from inefficient performance to significant damage or total failure.

4) What is the most effective method to enhance generator fuel efficiency?

There is no straightforward solution to enhance fuel efficiency; unlike automotive engines, generators are already optimized for efficiency. While incorporating turbines or additional components may provide temporary improvements, such modifications can adversely affect the overall longevity of the machine.

To ensure optimal performance, it is essential to maintain a consistent supply of quality fuel and fresh air, along with regular maintenance. This approach guarantees that the generator operates correctly when required and functions as intended.

We have observed numerous generators that struggle to start before undergoing repairs, consuming nearly double the necessary fuel, yet performing adequately post-repair. A generator that has not received maintenance for an extended period will only operate effectively once it has been serviced.

5) Is it feasible for a generator to achieve 100% fuel efficiency?

No engine in existence can claim 100% efficiency, with only a select few modern engines nearing 35% efficiency. The challenge lies in the conversion of the potential energy in fuel into electricity, which generates numerous byproducts that consume potential energy.

This process involves energy absorption during the movement of the piston, the combustion of fuel, and the subsequent operation of the electric motor to produce electricity. The combustion process generates heat, which is also absorbed by the wires.

The transmission of electricity through copper wires inherently results in some power loss. This is why cooler engines are highly regarded; an engine that requires minimal external heat is particularly impressive. However, it is important to note that internal combustion cannot achieve 100% efficiency.

6) At what load does the generator achieve optimal efficiency?

Generators reach their highest efficiency at a load of 75%. This indicates that the generator generates maximum power when operating at 75% of its capacity.

As the load increases, the efficiency of the generator improves. This enhancement is attributed to the generator’s ability to utilize fuel more effectively when functioning at elevated loads.

How to make generators use less fuel?

Strategies for Reducing Fuel Consumption in Generators

· Utilize only essential equipment.

· Ensure timely maintenance of your generator.

· Eliminate carbon buildup.

· Conduct maintenance punctually and use authentic replacement components.

· Consider alternative energy sources.

· Select a high-quality generator.

· Avoid overloading your generator.

· Ensure adequate ventilation.

Why is my generator using too much fuel?

Load variation—Generators exhibit increased fuel consumption when operating under higher loads, especially when approaching their maximum capacity. Optimal fuel efficiency is generally achieved at moderate, steady loads.

What is the best way to reduce fuel consumption?

Fuel Conservation Tips

· Accelerate gradually. The position of the throttle is the most critical factor influencing an engine’s fuel consumption.

· Avoid excessive speed, particularly on highways.

· Refrain from purchasing heavy vehicles with large engines.

· Do not opt for vehicles equipped with all-wheel drive systems, as most drivers do not require them.

How long does a liter of petrol last in a generator?

Approximately one hour

Fuel Consumption Rates:

Generators can operate longer on the same volume of fuel. Diesel engines are more fuel-efficient than petrol engines. A generator can function for about one hour on one liter of petrol and approximately two hours on one liter of diesel.