How to Fix Generator Power Surge Problem: 7 Powerful & Easy Solutions for Smooth Performance

To address issues related to generator power surges, it is essential to ensure the quality and quantity of fuel, maintain a clean air filter and carburetor, and inspect for any loose electrical connections or a malfunctioning Automatic Voltage Regulator (AVR).

Here is a more comprehensive overview:

1. Fuel Considerations:

· – Fuel Quality: Utilize fresh, high-grade fuel, as old fuel may lead to combustion issues and surging.

· – Fuel Filter: Regularly inspect and either Ensure proper fuel flow by cleaning or replacing the fuel filter.

· – Fuel Blockages: Examine the fuel lines for any blockages or restrictions.

2. Air Filter and Carburetor Maintenance:

· – Air Filter: A dirty or blocked air filter can hinder airflow, resulting in surging. It is advisable to routinely check and replace the air filter.

· – Carburetor: A contaminated or obstructed carburetor can disrupt the air-fuel mixture, leading to engine surging. Cleaning or replacing the carburetor might be required.

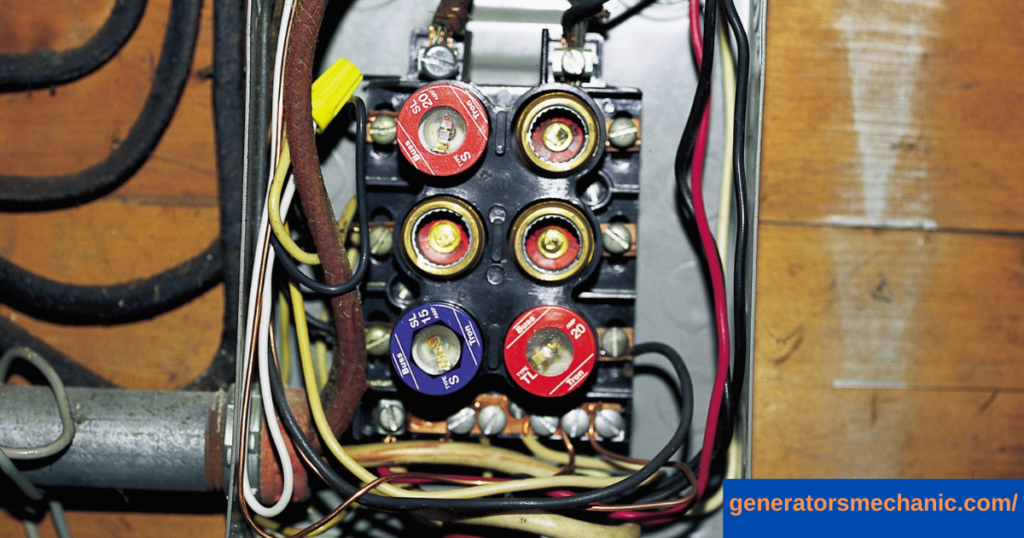

3. Electrical System Checks:

· – Loose Connections: Ensure that all electrical connections are secure, as loose wiring can create operational issues.

· – Automatic Voltage Regulator (AVR): A defective AVR may cause voltage fluctuations and surge. Testing or replacing the AVR should be considered.

· – Surge Protectors: Installing a surge protector or voltage regulator can help maintain a stable power supply and safeguard against voltage spikes.

4. Maintenance and Load Management:

· – Regular Maintenance: Conduct routine maintenance, including oil and air filter changes, to optimize generator performance.

· – Avoid Overloading: Prevent overloading the generator by ensuring that the total wattage of connected devices does not surpass its capacity.

· – Load Management: Gradually increase the load of connected devices and maintain balanced loads to prevent sudden surges.

5. Additional Considerations:

· – Check Oil Levels: Verify that the oil level is sufficient and that the correct type of oil is used.

· – Inspect Spark Plugs: Examine the spark plugs for signs of wear and replace them if necessary.

· – Consult a Professional: If there is uncertainty regarding any of these procedures, it is advisable to seek assistance from a qualified generator technician.

Power generators play a crucial role in both residential and industrial environments, offering backup power during outages or acting as primary energy sources in remote locations.

Nevertheless, like any intricate machinery, generators may occasionally encounter problems, potentially leaving you without power when it is most needed.

In this article, PC Inc Power Services will guide you through the steps to resolve issues with a generator that is not producing power or is running without generating any output.

Whether you are an experienced DIY enthusiast or a novice in generator repairs, we provide comprehensive step-by-step instructions, safety measures, and troubleshooting advice.

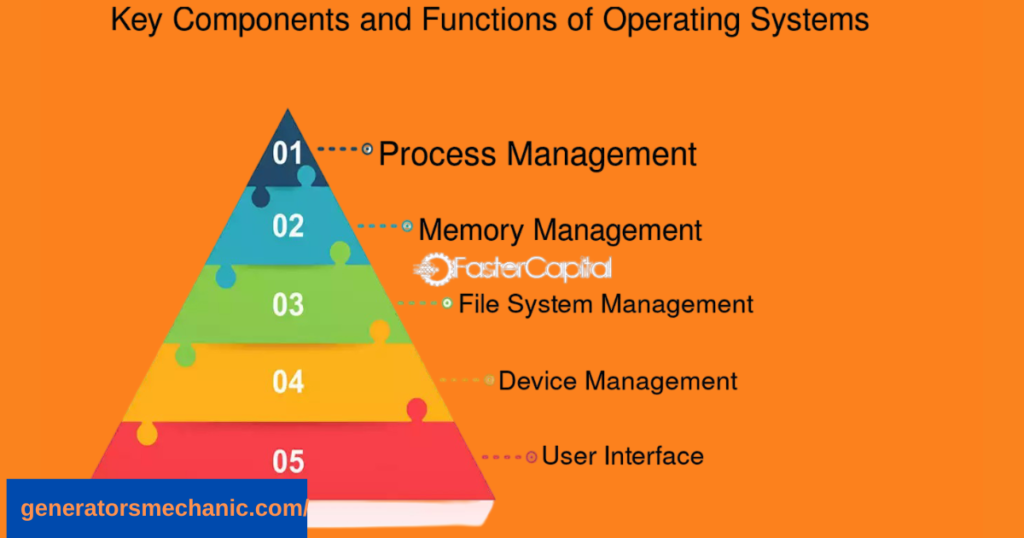

Understanding the Fundamentals: Key Components and Operation

A generator relies on its engine, alternator, voltage regulator, and fuel system to maintain stable power output. If even one of these parts falters, it can cause fluctuations or irregular surges in electricity.

Many users often ask, “Why is my generator revving up and down?”—and the answer usually lies in an imbalance between the fuel supply and engine performance. Dirty carburetors, clogged filters, or faulty governors can create instability, leading to sudden changes in RPMs. By carefully inspecting these key areas, you can pinpoint the root cause of surging and take the right steps to restore smooth, consistent operation.

Before delving into the repair process, it is important to understand the essential components and operation of a power generator.

A generator comprises an engine that drives an alternator to produce electrical energy. The engine can operate on various fuels, including gasoline, diesel, or natural gas, while the alternator generates electricity through the principle of electromagnetic induction.

We are here to assist you in addressing the issue of a generator that is not producing power, along with troubleshooting and repairing common generator malfunctions.

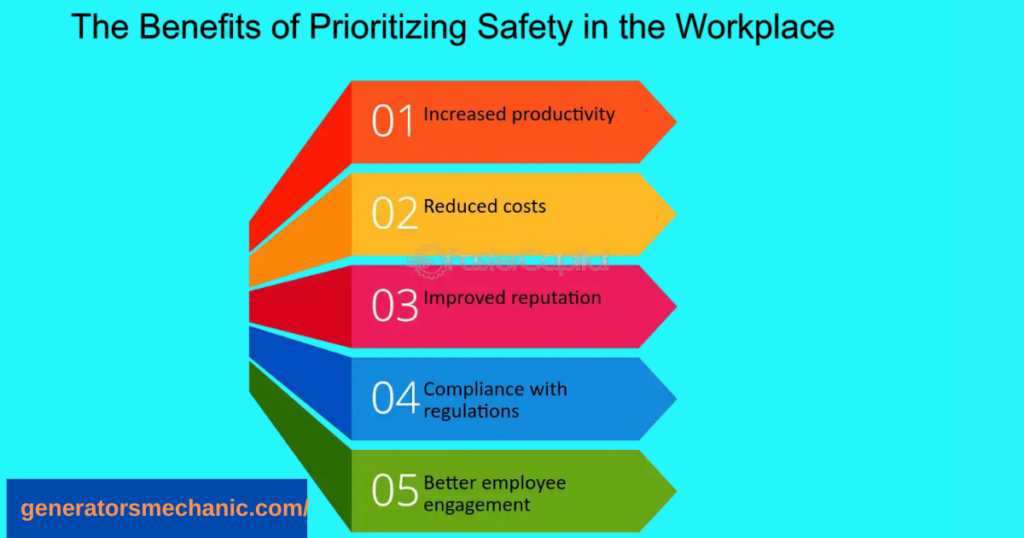

Prioritizing Safety – Preparing for Repairs

Generators deal with electricity and fuel, so taking proper precautions ensures you don’t risk injury or further damage. Always start by turning off the generator, disconnecting it from any appliances, and allowing the engine to cool down. Wearing insulated gloves and working in a well-ventilated area can also make the process safer.

If you’re dealing with brand-specific issues—such as wondering how to fix a generator power surge problem, Honda—you should carefully consult the user manual since different models may have unique maintenance requirements. By prioritizing safety and preparation, you’ll set the stage for effective troubleshooting and avoid costly mistakes.

Safety must be your foremost concern.

Adhere to the following guidelines to ensure a safe working environment:

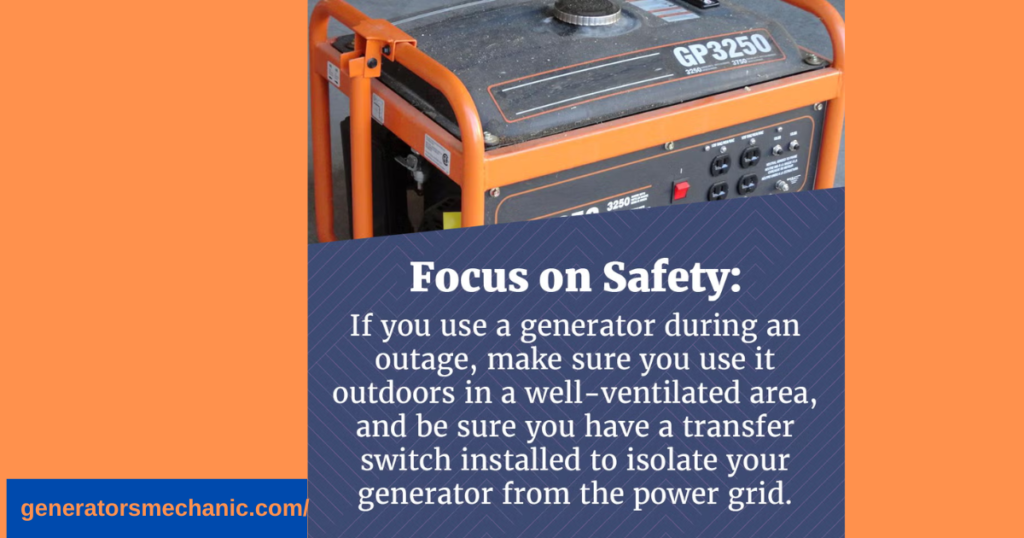

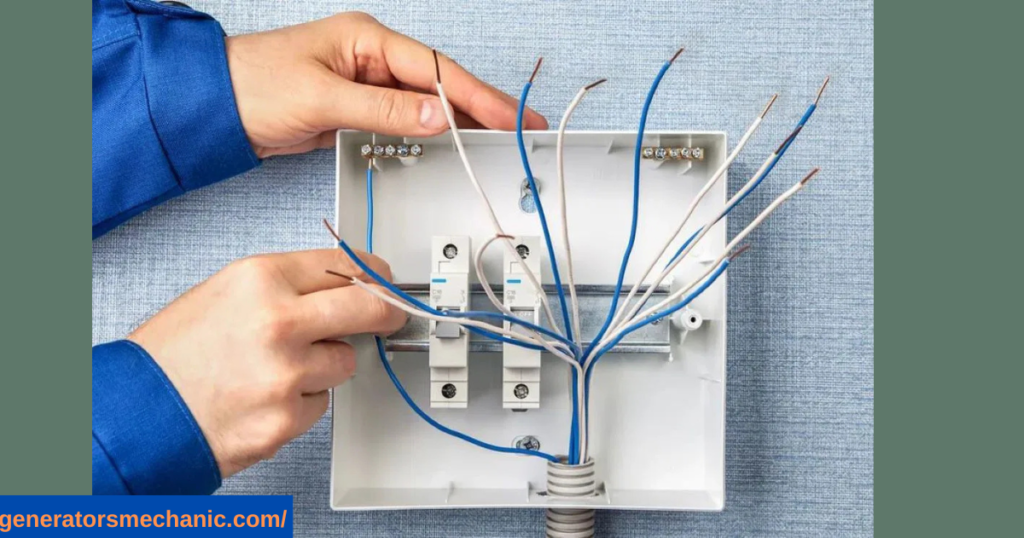

Disconnection and Isolation: Safely Disconnecting the Generator

Turning off connected appliances before shutting down the generator prevents sudden load drops that could worsen the surge. It’s also wise to switch off the main breaker to avoid any backflow of electricity into your home’s circuits. In cases of a diesel generator surging, proper isolation ensures that you can troubleshoot fuel supply, filters, or carburetor issues without risking further damage or safety hazards. Taking these steps not only protects your equipment but also keeps you safe while diagnosing the root cause of the problem.

Ensure that the generator is powered off and disconnected from the electrical grid to avoid the risk of accidental electrical shock.

Properly isolate the power source to prevent electricity from flowing back into utility lines, which could endanger utility personnel.

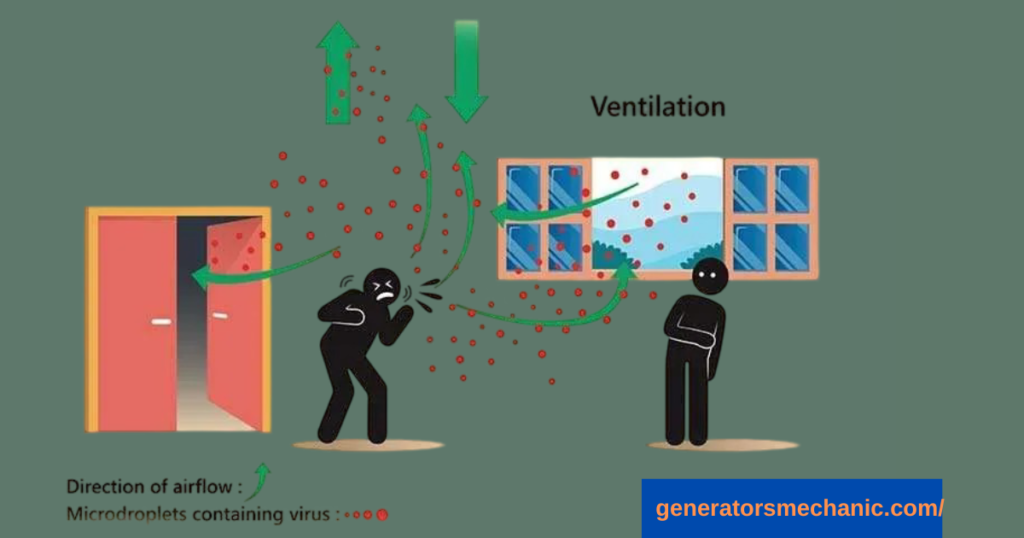

Adequate Ventilation: Establishing a Safe Working Environment

Generators need enough airflow to prevent overheating, which can directly affect their performance and even lead to surging issues. For instance, a Generac generator surging may often be the result of restricted airflow or clogged vents, causing the engine to struggle under pressure. By ensuring your generator is placed in an open, well-ventilated area, you not only improve its efficiency but also create a safer working environment free from harmful exhaust buildup. Proper ventilation is a simple but effective step toward maintaining consistent power output.

Select a repair location with good ventilation to prevent exposure to toxic fumes or exhaust gases.

Improve airflow in your workspace by using fans or working outdoors whenever feasible to reduce health hazards.

Tool Preparation: Assembling a Comprehensive Repair Toolkit

A well-equipped set not only saves time but also ensures accuracy in diagnosing and repairing issues. Your kit should include essentials like a multimeter for electrical checks, wrenches, screwdrivers, fuel system cleaners, and spare spark plugs. These tools give you the ability to handle both minor and complex fixes without constant trips to the store.

It’s also wise to prepare for situations where a brand-new generator surge might occur. Even new units can face power fluctuations due to incorrect setup, poor fuel quality, or factory misalignments. Having your toolkit ready allows you to address these issues quickly, ensuring your generator runs smoothly from day one.

Collect necessary repair tools, including wrenches, screwdrivers, multimeters, and any specific tools required for your generator model.

Ensure you have safety equipment such as gloves, goggles, and other protective attire to safeguard against potential risks.

Maintain emergency supplies like fire extinguishers and first aid kits within reach for unforeseen circumstances.

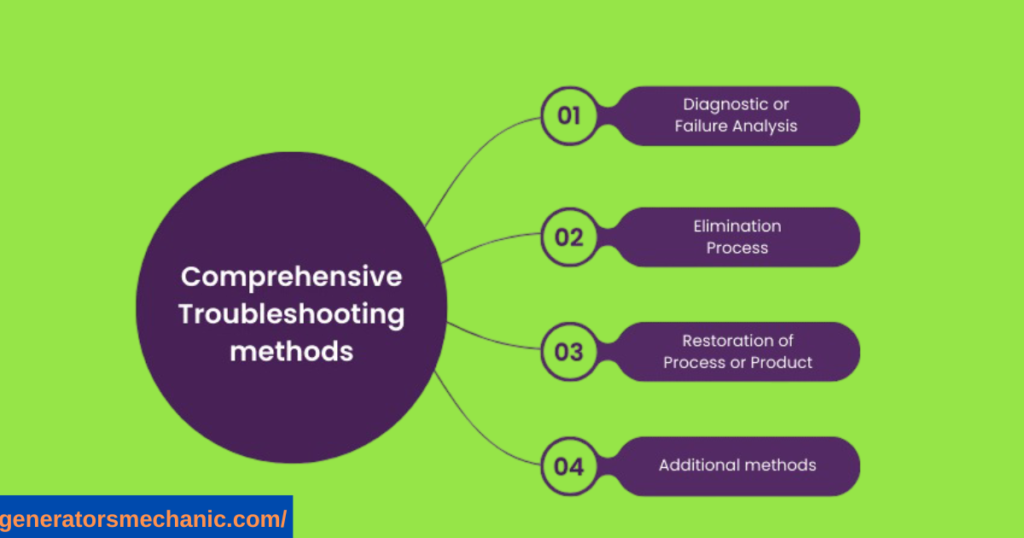

Common Generator Issues and Troubleshooting

Generators are reliable machines, but like any equipment, they can develop problems over time. One of the most frequent concerns users face is power surging, where the generator’s output fluctuates and causes unstable electricity flow. This issue not only affects performance but can also harm sensitive appliances if left unchecked. Understanding the root causes is the first step to finding a solution.

When it comes to how to fix a generator surging, the process usually involves checking a few key areas. Dirty or clogged carburetors, old fuel, blocked air filters, or faulty spark plugs are common culprits that trigger these irregular power spikes. By cleaning, replacing, or tuning these components, most surging problems can be resolved quickly. Regular maintenance and timely inspections ensure your generator continues running smoothly without interruptions.

Generators frequently encounter various issues, ranging from starting difficulties to electrical malfunctions.

Below are some prevalent problems along with their troubleshooting methods:

Diagnosing Starting and Running Problems in Engines

A common situation many users face is a generator surging with new carb, which often happens when airflow, fuel delivery, or carburetor adjustments are not balanced. Checking the fuel quality, cleaning the carburetor jets, and ensuring proper connections can significantly reduce surging. By taking a step-by-step approach to identify whether the problem lies in the carburetor, spark plug, or fuel line, you can restore stable power output and extend the overall life of your generator.

Verify the fuel supply and confirm that the fuel valve is in the open position.

Examine the spark plug for any signs of wear or buildup.

Verify the choke and throttle settings for proper adjustment.

Addressing Wiring, Output Malfunctions, and Electrical Glitches

Faulty connections, loose wires, or damaged outlets can cause irregular electricity flow that leads to sudden spikes. Carefully inspecting the wiring and ensuring all connections are tight can prevent these fluctuations. Another issue that users often face is the generator surging with no load, which usually points to problems in the carburetor, dirty fuel, or inconsistent voltage regulation. By cleaning fuel components, checking the AVR, and tightening electrical setups, you can significantly reduce surging and keep your generator running smoothly.

Examine the circuit breakers and reset them if needed.

Utilize a multimeter to test the output voltage and detect any electrical issues.

Inspect the wiring for indications of damage or loose connections.

Tackling Fuel Delivery, Lubrication, and Maintenance Problems

A clogged fuel line, dirty carburetor, or low-quality fuel can interrupt smooth engine performance, often leading to surging power output. Proper lubrication is equally important—lack of clean oil can cause internal friction and inconsistent operation. Many users ask, “Why is my generator revving up and down?” and in most cases, the answer lies in poor maintenance or irregular servicing. By keeping fuel filters clean, using high-quality oil, and sticking to a maintenance schedule, you can significantly reduce power fluctuations and keep your generator running smoothly.

Ensure proper fuel flow by cleaning or replacing the fuel filter.

Assess the oil level and replace it with the correct type if required.

Conduct regular maintenance activities such as changing the oil and air filters.

If you encounter a generator that operates but produces no power, these troubleshooting steps will assist you in identifying and addressing common issues.

However, should the problem continue or if you are uncertain about the diagnosis and repair, it is advisable to seek professional help.

Step-by-Step Repair Procedure

Let us proceed with the detailed procedure for repairing your power generator:

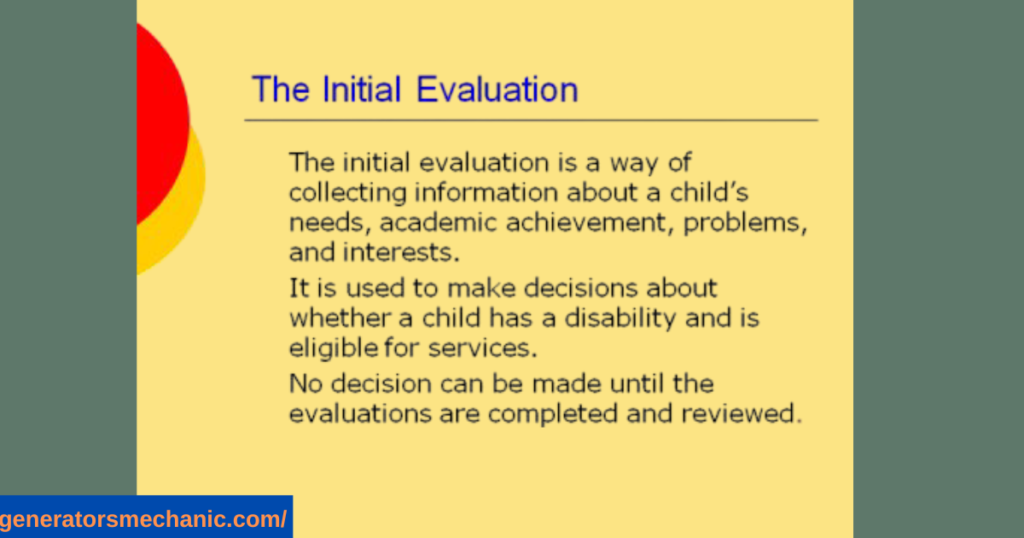

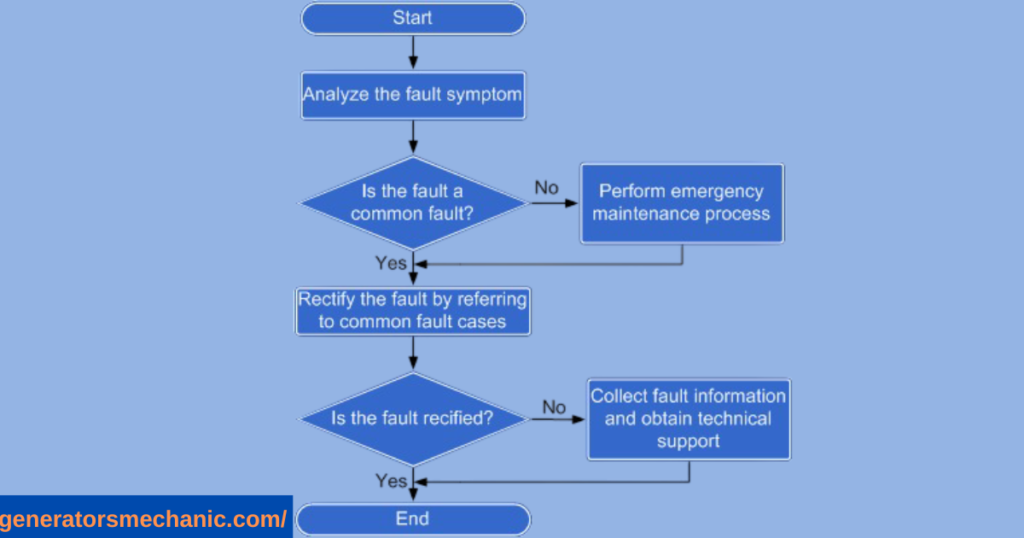

Initial Evaluation: Identifying the Issue

When dealing with a generator that suddenly produces inconsistent power, the first step is always an initial evaluation.. These warning signs often point toward issues like dirty carburetors, clogged filters, or faulty voltage regulators.

If you’re specifically concerned about how to fix a generator power surge problem, Honda, it’s important to note that Honda generators are highly reliable, but even they can develop surging issues due to minor maintenance lapses. Checking the fuel quality, cleaning the carburetor, and inspecting the air filter are practical first steps that can prevent further complications and restore stable performance.

Perform a thorough visual examination of the generator’s exterior to detect any visible damage or loose components.

Listen for any abnormal sounds or vibrations while the generator is in operation.

Employ diagnostic tools such as multimeters and voltage testers to accurately identify electrical problems.

Methodical Troubleshooting: Identifying Defective Components

Power surges are often linked to issues such as a clogged carburetor, dirty fuel filters, or inconsistent voltage regulation. A methodical approach means checking each part one by one, from the spark plugs to the alternator, to ensure everything is working as it should.

In some cases, problems can also be caused by a diesel generator surging, which usually points to irregular fuel supply or air intake issues. By inspecting fuel lines, cleaning air filters, and testing the governor system, you can narrow down the exact cause of the surge. This systematic process not only saves time but also prevents unnecessary replacements, ensuring your generator runs smoothly and efficiently.

Examine various subsystems, including the battery, fuel system, wiring, and control panel.

Check the battery for any charging or connection issues.

Follow the operational sequence to determine the specific component responsible for the malfunction.

Component Replacement: Exchanging Defective Parts

Worn-out spark plugs, clogged fuel filters, or damaged wiring can often trigger inconsistent power output. In some cases, issues like a Generac generator surging are directly tied to defective parts that no longer function as intended. By systematically inspecting and exchanging these components, you not only restore smooth power flow but also extend the overall lifespan of your generator, ensuring reliable performance during critical times.

Gain safe access to the internal components by adhering to the generator’s service manual.

Carefully remove, disconnect, and unfasten any damaged components.

Install the replacement parts, ensuring they fit properly and connections are secure.

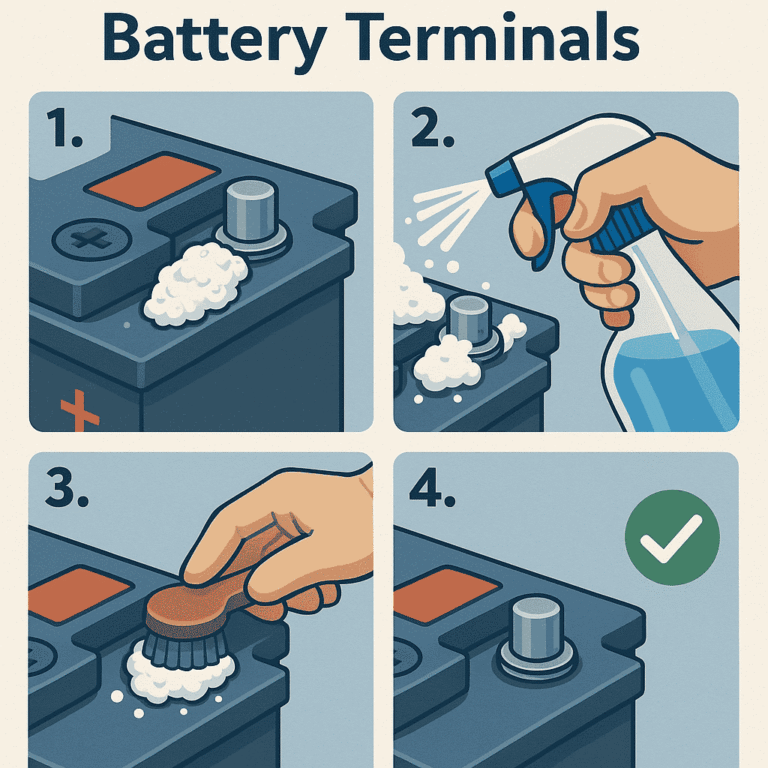

Restoration of Electrical Connections: Addressing Wiring Issues

Damaged electrical connections can interrupt the steady flow of current, causing fluctuations that lead to surges. Regularly inspecting cables, terminals, and connectors ensures a smoother and more reliable power output. In some cases, a brand-new generator surge may also point toward improper installation or wiring issues rather than a manufacturing defect. By carefully restoring and tightening electrical connections, you can often resolve surge-related problems and extend your generator’s performance life.

Conduct a visual inspection of the wiring for loose connections, corrosion, or damage.

Replace any damaged or frayed wires with suitable alternatives.

Verify that all connections are tight, insulated, and securely fastened.

System Testing and Calibration: Confirming Successful Repair

Running your generator under different load levels helps confirm whether the surging has been eliminated and ensures stable power output. During this phase, it’s important to monitor voltage consistency, fuel flow, and engine performance. If you’re still unsure about how to fix generator surging, professional calibration may be necessary to fine-tune the system and guarantee long-term reliability.

Reassemble any covers and housing that were removed during the repair process.

Restart the generator and observe its performance.

Ensure that all components are operating correctly and that the generator delivers the expected power output.

DIY vs. Professional Assistance: Determining When to Seek Expert Help

When it comes to how to fix a generator power surge problem, the first step is identifying whether the issue is something you can safely manage on your own or if it requires a professional’s touch. Many minor issues, like cleaning air filters or checking spark plugs, can be resolved through simple DIY steps.

However, more complex problems—such as a generator surging with new carb—might point to deeper mechanical or fuel system issues that need expert attention. Attempting to fix such problems without proper knowledge can make the situation worse. Knowing your limits is crucial: basic troubleshooting is fine for DIY, but persistent or technical surging problems should always be handled by a qualified technician.

Although many generator problems can be addressed through do-it-yourself methods, there are situations where enlisting the help of professionals becomes necessary.

Begin by evaluating your repair skills and your comfort level with complex machinery. If the problem involves sophisticated electrical components or necessitates specialized tools, it is advisable to seek professional guidance.

Additionally, select reputable repair services and technicians who possess experience in generator maintenance and repairs.

Preventive Maintenance for Extended Lifespan

Regular servicing not only ensures smooth operation but also prevents unexpected breakdowns that shorten the generator’s life. Cleaning air filters, checking spark plugs, and ensuring stable fuel quality are all vital steps to keep your unit running efficiently.

One common issue users face is a generator surging with no load, which usually points to clogged carburetors, dirty fuel lines, or improper idle settings. Addressing these small problems early through routine maintenance can prevent bigger, costly repairs down the road. By staying proactive, you extend your generator’s lifespan while ensuring it delivers steady, reliable power whenever you need it most.

To ensure your generator operates efficiently, regular maintenance is essential:

Arrange for periodic inspections and tune-ups to identify minor issues before they develop into larger problems.

Regularly check and maintain appropriate oil and fuel levels to guarantee dependable performance.

Ensure that both the generator and its surrounding area are kept free from debris and dust.

Emergency Troubleshooting Tips

Start by inspecting the fuel supply and air filter, as clogs or low-quality fuel can often cause uneven performance. Next, check the load you’ve connected—an overloaded generator can easily trigger surges.

One common question users ask is, “Why is my generator revving up and down?” This usually happens due to carburetor issues, dirty fuel, or a malfunctioning governor. Cleaning or replacing these components often stabilizes the engine’s performance. Keeping your generator well-maintained, using fresh fuel, and balancing loads properly are the fastest ways to troubleshoot and minimize power surges during emergencies.

In critical situations, these quick solutions can prove invaluable:

If the generator does not start during a power outage, verify the fuel level, battery charge, and starter motor functionality.

Always adhere to safety protocols when performing urgent repairs, prioritizing your safety and that of those nearby.

Maximizing the Benefits of Fully Functional Power Generators

A well-maintained generator can make all the difference when it comes to an uninterrupted power supply for your home, RV, or business. Fully functional power generators don’t just provide electricity during outages; they also ensure efficiency, safety, and long-term reliability. Regular servicing, proper load management, and timely inspections help maximize their benefits by preventing costly breakdowns and keeping performance consistent.

At times, users may face technical issues like power fluctuations, which can impact performance. If you’re wondering how to fix a generator power surge problem, Honda, the solution often lies in routine maintenance—such as cleaning carburetors, checking voltage regulators, or replacing faulty capacitors. By addressing these small concerns early, you can ensure your generator delivers stable and dependable power when you need it most.

In addition, addressing a power generator that is either non-operational or running without producing electricity necessitates a thorough diagnosis, appropriate tools, and a strong emphasis on safety.

By adhering to the procedures and recommendations outlined in this article regarding the resolution of generator power issues, you can effectively tackle common problems and restore dependable power generation for your residence or business.

Our team at PC Inc Power Services is readily available to provide you with expert generator repair and maintenance solutions. Reach out to us today to guarantee the continuity of your power supply.

Conclusion

Fixing a generator power surge problem requires a systematic approach, starting with identifying the root cause. Common culprits include dirty or faulty carburetors, unstable fuel supply, damaged capacitors, or malfunctioning voltage regulators. Regular maintenance, such as cleaning the carburetor, checking fuel quality, and inspecting electrical components, can prevent surges and ensure stable power output. If troubleshooting doesn’t resolve the issue, seeking professional assistance is recommended to avoid further damage. By taking proactive steps, you can keep your generator running efficiently and safely for long-term use.

Frequently Asked Questions (FAQs)

What steps should I take to fix a generator that is not producing power?

Begin by inspecting the circuit breakers and resetting them if needed. Assess the generator’s voltage regulator and brushes for any potential problems. Furthermore, check the rotor and stator for any indications of damage or wear. If you are still uncertain about how to resolve a generator that operates but does not generate power, it is advisable to seek professional assistance for a comprehensive diagnosis and repair.

How frequently should I arrange for generator maintenance?

Consistent maintenance is vital for ensuring the durability and reliability of your generator. The maintenance schedule should be influenced by factors such as usage, environmental conditions, and the type of generator. As a general recommendation, it is advisable to schedule maintenance at least once a year. This annual inspection enables technicians to evaluate essential components, replace oil and filters, and detect any potential issues.

What actions should I take if my generator produces an excessive amount of smoke?

The hue of the smoke can provide insights into the underlying issue:

Black Smoke: This often suggests a problem with fuel combustion. It is advisable to inspect the air filter, assess the quality of the fuel, and evaluate the fuel delivery system. Black smoke may arise from incomplete combustion caused by a blocked air filter or an imbalanced fuel-to-air ratio.

Blue Smoke: The presence of blue smoke generally indicates oil consumption during the combustion process. This may result from worn piston rings, valve seals, or other internal engine complications. It is recommended to consult a professional for accurate diagnosis and resolution of the issue.

White Smoke: White smoke may indicate that coolant is entering the combustion chamber, potentially due to a blown head gasket or a fractured engine block. This situation is serious and necessitates immediate attention from a qualified technician.

Is it advisable to repair a generator during a power outage?

Attempting to repair a generator during a power outage introduces additional hazards due to the absence of available power and the risk of electric shock. Before undertaking any repairs, ensure that the generator is entirely disconnected from both the electrical grid and any attached devices. While performing maintenance on the generator, adhere to stringent safety protocols, including the use of appropriate personal protective equipment (PPE) such as insulated gloves and goggles. If you are uncertain or uncomfortable with repairing generators, it is safer to wait until power is restored or to seek professional assistance.

Can I utilize any type of oil for my generator’s engine?

It is essential to use the specific type of oil recommended in your generator’s manual. The engine oil designated for a generator possesses particular properties and viscosity ratings that are tailored for optimal engine performance and temperature regulation. Employing an incorrect type of oil can result in diminished engine efficiency, increased wear, and potential engine damage.

How do you stop a power surge from a generator?

Utilizing a surge protector in conjunction with a generator to safeguard sensitive devices connected to it not only shields those devices but also spares you from significant inconveniences. A surge protector functions by absorbing and redirecting excess electrical power, thereby preventing device overloads that could lead to irreversible damage.

How do I stop my generator from surging?

The generator may experience surging due to an excessively low idle setting. Located at the center of the carburetor is a large black cross-head screw, which regulates the idle position of the throttle plate. Adjust the screw in a clockwise direction until the surging ceases.

Can a generator cause a power surge?

Additionally, an uneven load on the generator can contribute to surging. To ensure a consistent engine speed and stable electrical output, it is essential to distribute the load evenly across the generator’s capacity.